Description

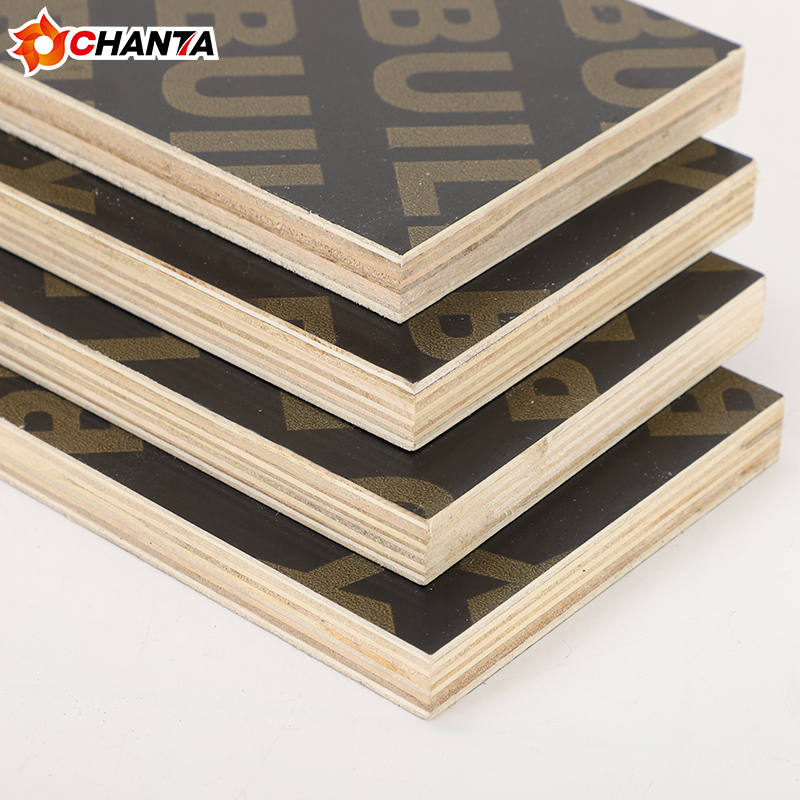

F17 film faced plywood

Chanta F17 Film Faced plywood is plywood made with a high-density overlay of Phenolic resin infused paper bond to give you an amazing off form finish and it’s structural integrity allows multiple reuses across the Concrete, Building and Construction Industries.for strong, stable, concrete formwork.

Chanta F17 Film Faced Plywood is a high quality formwork plywood developed and engineered specifically for the Australian market.

With a three tier quality control program comprising;

Regular, detailed and recorded in house testing on key quality requirements and independent grading,

Testing and certification carried out by Certemark Iternational (CMI) and DNV.

Provides assurance of quality and consistency.

All veneer in the manufacture is certified Forest Stewardship Council (FSC) from sustainable forests.

Advantage

High Structural Performance:F17 film faced plywood is specifically engineered for high-performance structural applications. Meeting stringent F17 standards, it delivers exceptional strength and reliability for demanding construction projects.

Smooth, Durable Surface:The phenolic film coating provides a smooth, high-quality finish, ideal for concrete formwork and other applications requiring an even surface. This film layer also resists water, wear, and chemicals, extending the product’s lifespan across multiple uses.

Enhanced Core Strength and Stability:Constructed with a robust hardwood core, this plywood is exceptionally durable and stable under heavy loads. Its structure prevents warping or bending, ensuring stability in any demanding environment.

Water and Scratch Resistance:The edges of it are sealed with waterproof paint, adding extra moisture protection. Additionally, its scratch-resistant surface maintains appearance and functionality over repeated use.

Lightweight and Easy to Handle:Despite its high strength, F17 film faced plywood is lightweight, making it easier to transport and install. This feature reduces labor costs and simplifies handling on-site, even in large-scale projects.

Versatile Applications:This plywood is highly versatile, fitting well in a wide range of construction and industrial projects. Whether for formwork, heavy-duty flooring, or structural frameworks, it meets the needs of diverse projects efficiently and reliably.

EXCELLENT MATERIAL SELECTION

Using solid log wood boards, the material undergoes thorough sterilization through high-temperature and high-pressure processing.. Low moisture content, suitable for most environments.

NOT EASY TO DEFORM

LONG USE TIME

Good toughness, stable performance, fine wood texture, not easy to deform and split.

Reviews

There are no reviews yet.