Chanta Company Profile

Chanta Group is a multinational enterprise integrating industry and trade.Founded in the year of 1995 and owning 6 factories with 1000 people in China and Gabon.Main products are commercial plywood,film faced plywood,fancy plywood and laminated board.

Under the value of Customer first, Honest and trust worthy,Chanta quality is warmly welcomed by all of the world.Until now,our export volume has reached the top two in China and obtained AEO certification issued by the General Administration of Customs.2 Factories in Gabon Africa,1 Factory in Vietnam,More than 900 production workers.

You are welcome to visit us for cooperation

Contact us for the latest prices and stock listings

+8615806905577

Hot Sell Plywood

CHANTA® is committed to producing high-quality plywood. The superior durability and versatility of our plywood bring better performance and value for a better life.

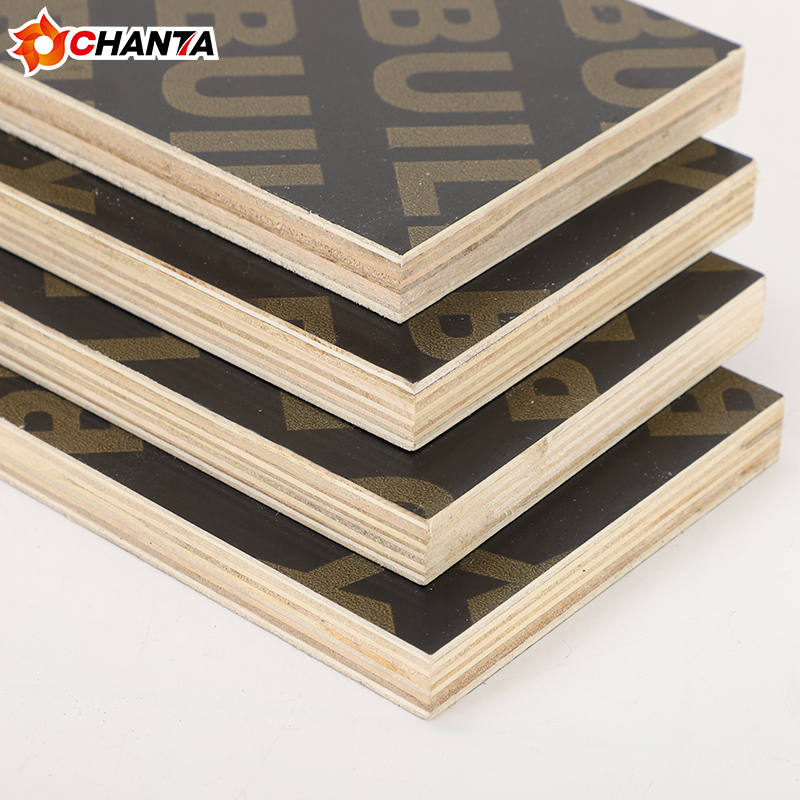

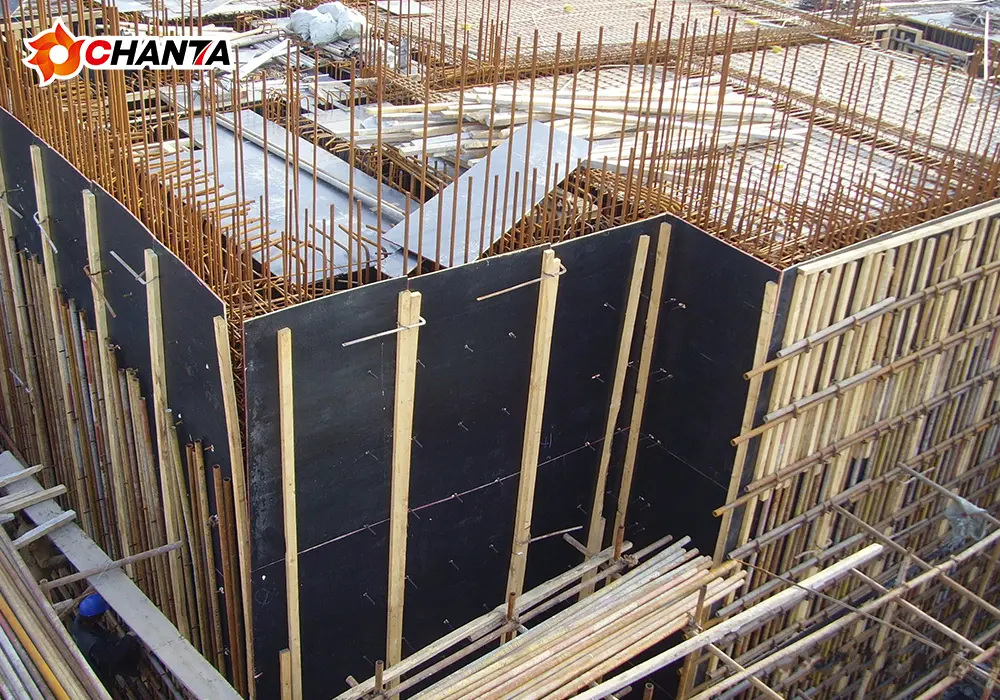

CHANTA® Film Faced Plywood – Durable, Waterproof, and Built for Strength! Ideal for concrete formwork, our high-quality plywood ensures multiple reuses, smooth finishes, and superior performance on every project

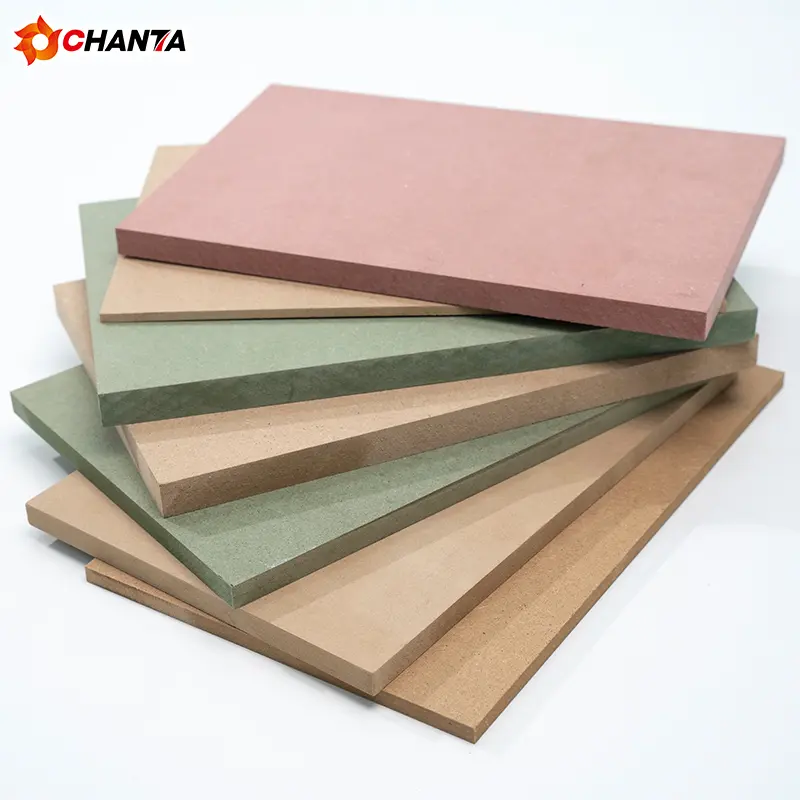

CHANTA®Melamine Board – Stylish, Durable, and Easy to Maintain! Perfect for furniture, cabinets, and interior decor, our high-quality melamine board offers a smooth finish, scratch resistance, and long-lasting performance for any space.

WHY CHANTA

CHANTA® has 30 years of export experience serving more than 150 countries worldwide. 100% on-time delivery rate.

MARKET EXPERTISE

Advanced production technology with a dedicated R&D team. We provide timely market insights and competitive pricing.

GLOBAL UNDERSTANDING

Our CEO speaks fluent English and has extensive global business experience, ensuring smooth communication.

TRUST & RELIABILITY

We are a responsible and trustworthy partner, offering reliable after-sales support for all our clients.

QUALITY TRACKING

Independent inspection systems and complete production tracking ensure the highest product quality.

Blog&Posts

Which products are you interested in? Commercial plywood, Film faced plywood, MDF, Melamine board, Chipboard, or something else? Here, you can find the answers you’re looking for!

How Many Times Can Film Faced Plywood Be Reused?

One of the most important questions contractors, developers, and importers ask before purchasing formwork panels is simple: how many times can film faced plywood be reused? The answer directly affects budgeting, cost control, and project efficiency. In large construction projects, even a small difference in reuse cycles can significantly change…

Black Film Faced vs Brown Film Faced Plywood: What’s the Real Difference?

Black film faced plywood and brown film faced plywood are widely used in concrete formwork. Many buyers assume that color indicates quality level, durability, or reuse performance. In reality, the difference between black and brown film faced plywood goes beyond appearance but does not automatically determine overall performance. Understanding what…

How Many Times Can Film Faced Plywood Be Reused?

One of the most common questions contractors and importers ask is: how many times can film faced plywood be reused? The answer directly affects project cost per square meter and overall material efficiency. Film faced plywood is designed for concrete formwork and repeated use, but the actual reuse times depend…

What Does “Film Faced” Mean in Plywood?

The term “film faced plywood” appears frequently in construction projects, formwork specifications, and plywood quotations. Many buyers understand that film faced plywood works well for concrete formwork, but fewer understand what “film faced” actually means and why it changes plywood performance. In plywood, “film faced” refers to a protective surface…

MDF Wholesale MOQ and Container Loading Guide

MOQ and container loading directly affect cost, delivery efficiency, and sourcing flexibility when importing MDF at wholesale level. Many importers focus on board price but overlook how minimum order quantities and loading methods impact total landed cost. This guide explains how MDF wholesale MOQ works, how different container loading methods…

MDF Manufacturer vs Trader: What Importers Should Know

When importing MDF in bulk, one of the first decisions importers face is whether to work with a manufacturer or a trading company. Many sourcing problems—quality inconsistency, delivery delays, or unclear responsibility—do not come from MDF itself, but from choosing the wrong type of supplier. This article explains the real…

MDF Wholesale Guide for Importers

Importing MDF at wholesale level requires more than comparing prices. Many importers face issues such as inconsistent quality, unclear specifications, hidden costs, and shipment delays. These problems often come from incomplete supplier evaluation and unclear purchase requirements. This MDF wholesale guide explains how importers evaluate suppliers, specify products correctly, control…

How MDF Is Made: From Wood Fibers to Panels

MDF may look like a simple engineered board, but its performance depends heavily on how manufacturers turn raw wood into finished panels. Differences in fiber preparation, resin bonding, and pressing control often explain why some MDF panels perform well while others fail in furniture and cabinet applications. MDF is made…

Why MDF Swells When Wet (and How to Reduce the Risk)

MDF swelling remains one of the most common problems buyers face after installation. Cabinets, furniture panels, or decorative boards may look perfect at first, but once moisture appears, the damage often becomes permanent. This article explains why MDF swells when it gets wet, which situations create the highest risk, and…

When You Should Not Use MDF

MDF works well in many furniture and interior applications, but it does not fit every situation. Buyers who use MDF in the wrong environment or for the wrong purpose often face swelling, joint failure, and early product damage. This guide explains when buyers should not use MDF and what problems…

E0 vs E1 MDF: What Buyers Should Know About Emissions and Safety

Formaldehyde emission levels play an important role in MDF purchasing decisions. Many buyers see E0 and E1 grades listed in quotations, but they often feel unsure about what these labels really mean and how much difference they make in real use. This article explains the difference between E0 and E1…

What Is the Density of MDF? Why It Matters for Furniture and Cabinets

MDF density plays a major role in how the board performs in real applications. Many buyers focus on thickness and surface finish, but density directly affects strength, weight, screw holding, and long-term durability. This article explains what MDF density means, typical density ranges, and how buyers choose the right density…

CUSTOMER PHOTO

We are trusted by our customers and we look forward to working together.