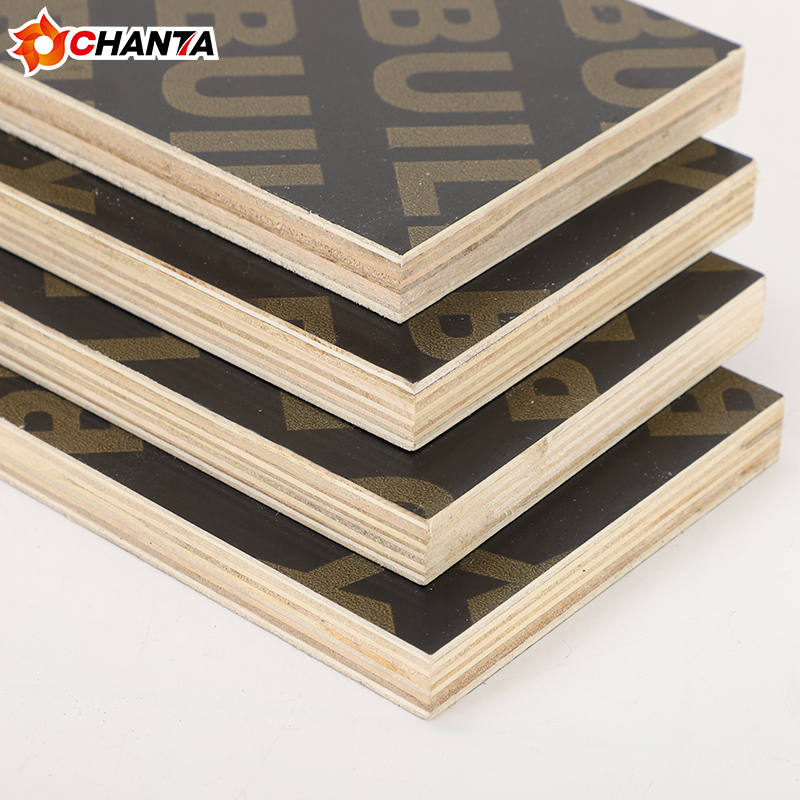

Film Faced Plywood

Size: 1220x2440mm, 1250x3000mm, or Customized

Thickness: 2.7~30mm (4mm, 6mm, 9mm, 12mm, 18mm)

Face/Back: Theil Film, Black Film, Brown Film, Red Film, Or Logo Film

Core: Birch, Eucalyptus, Combi, Poplar core or request

Reuse: 4–6 times, 8–12 times, 15–20 times, 20–25 times

Glue: Phenolic, WBP

Certificate: FSC, CE, EUTR, CARB, EPA

Usage: Construction, Formwork system, shuttering, etc

Product advantages:1. Waterproof and boil glue in water 2. Smooth surface, high wear resistance 3. It can be reused 5~30 times when used correctly 4. High Strength and Stability

Table of Contents

Core material

Film types

The film is opaque.It is literally kraft impregnated with melamine glue or phenolic glue. Usually generic brands or taier brand.

It can increase the use of plywood, waterproof and flame retardant effect.

Film color can be black color, brown color, red color or green color. OEM and ODM are also available.

Glue types

The primary feature of WBP glue is its ability to resist water and moisture. This makes it ideal for outdoor applications and environments where the bonded materials may be exposed to water.

WBP melamine glue can withstand boiling water, which is a testament to its superior water resistance. This property is particularly important for applications where the adhesive will be exposed to extreme moisture.

WBP glue is widely used in the manufacture of film faced plywood, outdoor plywood, and other wood products that require high resistance to water and outdoor plywood.

Applications in Construction & Beyond

1. Construction Use: Formwork and Shuttering

Film faced plywood is primarily designed for use in the construction sector, particularly for making concrete molds such as formwork panels, shuttering boards, and construction templates. Because of its exposure to water during concrete pouring, most buyers prefer WBP film faced plywood for large-scale or structural projects, due to its enhanced water resistance. For smaller or less demanding applications, MR glue film faced plywood is sometimes selected as a cost-effective alternative.

2. Anti-Slip Flooring for Vehicles and Work Platforms

Depending on surface type, film faced plywood comes in smooth or anti-slip finishes. The anti-slip variant is commonly used for flooring in trucks, trailers, and scaffolding platforms, providing extra grip and safety in work environments.

3. Furniture and Storage Applications

Thanks to its tough surface coating and superior durability, film faced plywood can also be used for producing sturdy shelves, storage racks, and long-lasting furniture. Compared to traditional plywood with wood veneer, it offers better resistance to wear, moisture, and daily impact.

Our brand

Regarding the film faced plywood product, our Chanta Group has BUILDPLEX, CHANTAPLEX, LORDOLEX,ROCKMARINE,

MARINEPLEX,BUILDBOND and other different brand products targeting different markets.

FAQ

1. What exactly is film faced plywood?

Film faced plywood is a type of engineered plywood covered with a resin-treated film. The film gives the board a smooth surface and makes it resistant to moisture, abrasion, and chemicals—ideal for use in concrete formwork and outdoor applications.

2. Can this plywood handle wet or humid conditions?

Yes, film faced plywood offers strong water resistance. Manufacturers apply a waterproof film to the surface and use WBP glue between layers. While it is not 100 % waterproof like plastic, it holds up well in wet environments when properly sealed.

3. Where do builders usually use this material?

Builders mainly use film faced plywood for concrete formwork in construction. The smooth, durable surface prevents concrete from sticking, allowing multiple reuses. It’s also used in flooring, scaffolding, truck beds, and outdoor furniture frames.

4. How many times can a single panel be reused?

It depends on quality and handling, but high-grade film faced plywood can be reused up to 10–15 times in concrete pouring projects. Proper cleaning and storage between uses will extend its lifespan.

5. What thickness options are available?

Common thicknesses range from 9 mm to 21 mm, with 18 mm being the most widely used in construction. Thicker panels provide more strength and support for heavy-duty applications like formwork and flooring.